-

Call us

262-947-0707

Call us

262-947-0707

Electrical contact or connection failure can spell disaster for your facility or appliance’s operations. Issues with these systems can cause costly damage to capital equipment, not to mention injury or loss of life. Maintaining well-functioning electrical contacts is an important element to ensuring the performance and safety of your electronic equipment and components.

An electrical contact a switch that uses a secondary, low-voltage power source to complete or interrupt circuits that affect an electrical current. Unlike relays, they carry higher circuit loads and connect directly to high-voltage feeds, and they don’t interrupt short circuits like circuit breakers.

Electrical contacts consist of three basic parts:

By sending low-voltage power through the coil, the electromagnetic current activates the movable contact to open (thereby interrupting current flow) or close (thereby completing the circuit) against the stationary contact.

Electrical contacts are common in electrical mechanical devices that operate with a broad range of voltages and functions. Some of their most important uses include in:

These specialized switches come in two different contact states: normally closed (NC) and normally open (NO).

Depending upon the specifics of applications that use electrical contacts, either a normally closed or normally open contact will be installed. It’s important to know the difference between each type of system so you can determine the correct choice for your application.

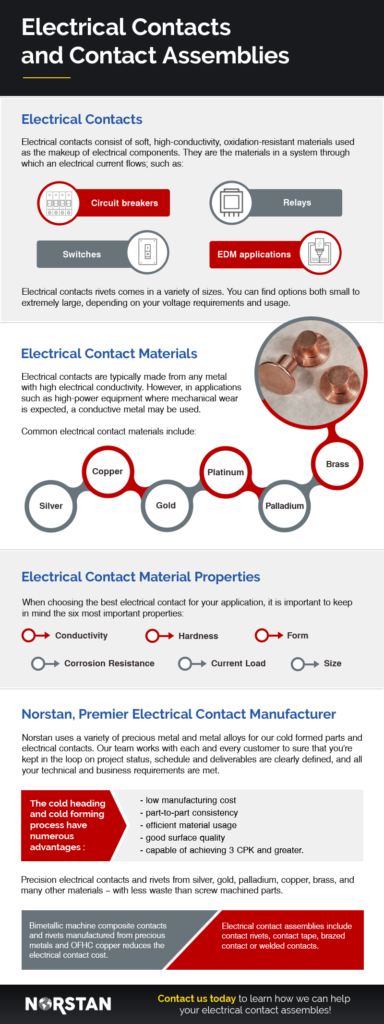

Building properly functioning electrical contacts requires the use of materials with:

Among the common metals used to create electrical contacts are:

Each of these metals has essential properties that make it a proper fit for various electrical contact installation types and functions.

Choosing the right electrical contact for your application will significantly improve its reliability and performance within the system.

There are six essential properties to consider when making this choice:

1. Conductivity: This measures a metal’s ability to resist or conduct electric currents as specified by the International Annealed Copper Standard (IACS); in this system, copper establishes the baseline at 100% conductivity, and other metals are rated in accordance to their capacities

2. Corrosion resistance: This relates to the ability of the contacts to resist chemically induced corrosion over time

3. Hardness: This evaluates four resistance or deformation factors under applied pressure, including:

4. Current load: This refers to the maximum current load capacity of the material

5. Form: This specifies the various shaping capacities of the material for its specific application

6. Size: This measures the length, width, and thickness of the material or its outside diameter in relation to its application

Bad electrical contacts or electrical contact failure affects both the performance and safety of the components and systems they serve. Contact failure increases the resistance of the conductor and prevents proper current flow.

Corroded battery cables on an automobile are a common example of electrical contact failure, which can lead to a breakdown in vehicle performance. In critical cases, electrical contact resistance causes overheating or cooling failures that can result in explosions, which compromise the safety and security of operators and the facility as a whole.

Reducing contact resistance starts with choosing the proper electrical contact material according to the six essential steps provided above, periodically inspecting and replacing worn contacts, or cleaning and maintaining corroded electrical contacts.

Operators must regularly clean electrical contacts to reduce their contact resistance and ensure good operational safety and performance. Many electrical contacts can be cleaned using common household items by following these steps:

While cleaning oxidation and corrosion from contacts, be sure to inspect the various elements of the system for weakness or wear. Replacing electrical contacts before they wear out, become too resistant to electricity, or fail completely results in significantly improved cost savings and security advantages.

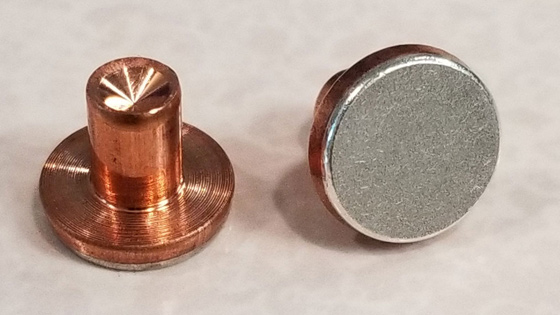

Norstan is a leading manufacturer of highly specialized precision electrical contacts. Our products operate within a wide variety of applications, including:

We’re also a leading OEM and supplier of electrical parts across a broad range of industries. From our Wisconsin facility, we produce:

Our team members strive to ensure that every customer remains up to date on project status, schedule, and delivery, and we constantly strive to meet or exceed your technical and organizational requirements. Norstan’s cold forming processes yield a number of benefits for our clients, including:

We’ve applied more than 50 years of experience toward producing the highest-quality products at the most competitive prices available in the industry. We also rely on our excellent customer service and sales representatives to help develop custom solutions that match your unique needs. Production of our electrical contacts occurs in an ISO:9001-registered facility with a commitment to providing a complete, cost-effective solution for our clients.

Electrical contacts are a vital element in ensuring the performance and safety of electromechanical devices and systems.

Contact us to learn more about how Norstan can help you improve or maintain your electrical systems.