The Most Common Failure Scenarios for Electrical Contacts

Quincy Clegg

Often, when a product or component fails, it’s because it wasn’t adequately designed for the…

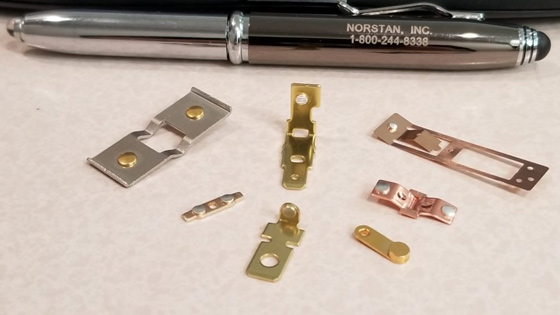

Key Factors When Choosing an Electrical Contact Supplier

Quincy Clegg

When it comes to electricity, a strong connection makes everything go. Current flows unimpeded, like…

Auto-Wire & Tape Weld Electrical Contact Welding Process

Quincy Clegg

The auto-wire weld assembly process develops a metallurgical bond between the precious metal piece (wire)…

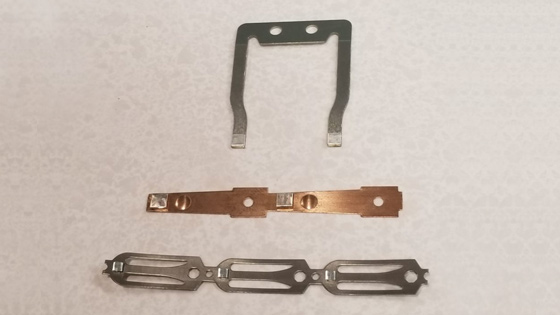

Benefits of Precision Stamping Custom Electrical Contacts

Quincy Clegg

Precision Metal Stamping Metal stampers are using high-speed presses and stamping dies to form metal…

Surface Contamination and Electrical Contact Resistance

Quincy Clegg

Correlation of Surface Contamination Introduced by Feeding Equipment on Electrical Contact Resistance Abstract Contact degradation…

The Effect of Various Deburring Media Containing Mineral

Quincy Clegg

The Effect of Various Deburring Media Containing Mineral SILICON (SiO2) OR ALUMINUM OXIDE (A1,0.) ON…

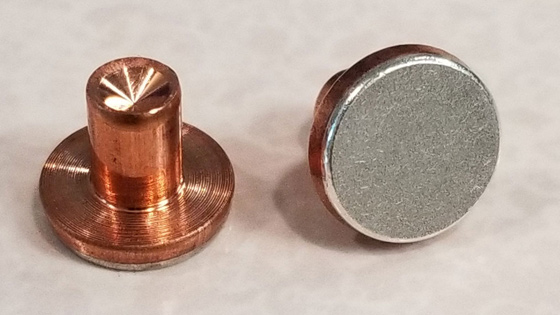

Everything You Need To Know About Electrical Contacts

Quincy Clegg

Electrical contact or connection failure can spell disaster for your facility or appliance’s operations. Issues…

Differences Between Spot Welding & Projection Welding

Quincy Clegg

The resistance welding process is commonly utilized in budget projects because it requires no additional…

Differences Between Soldering & Furnace Brazing Contacts

Quincy Clegg

What’s the Difference Between Soldering and Furnace Brazing? Furnace brazing joins metals by melting a…

How to Find a Reliable Custom Electrical Contact Supplier

Quincy Clegg

Imagine if your automobile had rope steering, like an old-fashioned go kart. You could steer…